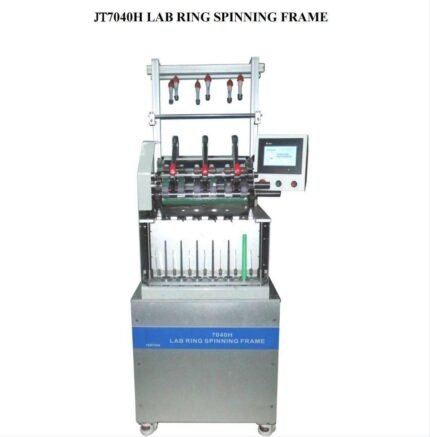

Lab ring spinning frame

$1,339.00 Original price was: $1,339.00.$803.40Current price is: $803.40.

Description

FEATURES:

- Lab ring spinning frame

- Delta brand PLC, drive, servo motor;

- Use S/Z twist turning;

- Rotation speed of spindle accurate to ±1%;

- Aluminum profile body frame with four casters, free to move;

- Modular independent drive for drafting, spindle blade and flyer;

- PLC + touch screen control, easy to learn and operate;

- Use touch screen as man-machine interface, input technical parameters and show

machine running state by touch screen; - Multi-functional design, easy to clean, set and maintain;

KEY SPECIFICATION:

- Control mode Touch screen & PLC

- Number of spindles 6

- Applicable fiber length 22~50mm

- Draft range 10~50

- Draft control Automatic

- Roller diameter Front roller: Φ25mm, middle roller: Φ25mm, back roller: Φ25mm

- Center distance of rollers Front and middle: 43mm

- Front and back: 143mm

- Pressure mode Spring cradle

- Twist settable range 200~2000 twist/m, twist direction S or Z

- Max. speed of spindle 12,000rpm

- Spindle gauge 70mm

- Spindle length 205mm

- Ring diameter Φ42mm

- Yarn density range 6~99tex (6~100Ne)

- Capacity Approx. 0.25~1kg/h

- Power supply AC220V, 50Hz

- Dimensions 1,000*750*1,700mm

- Net weight 430kg

Related products

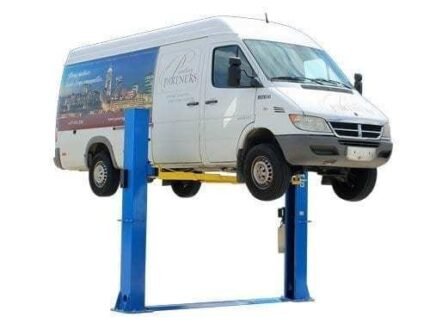

Car Bench UL300 Auto Body Collision Repair System Frame Machine 7700 lb Capacity

UL-300, small size bench welded made of cold high-alloy rectangular tubes is designed professionally for body collision quick repair by choosing better material, improving welding technique and enhancing stress intensity to make the repairing work more precise and faster. In accordance with European advanced technology, simple, practical, safe and precise for fast repair.

Lab Ring Spinning Frame

A Lab Ring Spinning Frame is a machine used in textile manufacturing for small-scale production or research and development. It produces yarn from staple fibers and consists of a creel, drafting system, twisting mechanism, and winding system. The drafting system pulls fibers into a fine strand, the twisting mechanism adds strength, and the winding system packages the finished yarn onto a bobbin.